Durability is an essential consideration in selecting materials for any construction project. These days, metal, steel, or plastic pass to this standard and are commonly used. But, of course, one of these emerges more formidable and long-lasting.

The durability factors of a material

Durable material is a material that can withstand repeated use or exposure to elements without deteriorating. It is often determined by its ability to resist wear and tear, fading, chipping, or other forms of damage. Some are naturally excellent, while others need treatment to increase their durability.

There are three main types of durability:

- Physical durability refers to a material’s capability to withstand physical forces such as wear and tear.

- Chemical durability is a material’s resistance to chemicals or other substances that may cause it to deteriorate.

- Biological durability has something to do with a material’s power to withstand organisms that may cause it to degrade.

The durability of a material can also be affected by its environment; for example, some materials may be more durable in cold climates than in warm temperatures.

Materials can be both durable and non-durable. Non-durable materials, such as paper or cloth, will deteriorate with constant use or exposure to elements such as sunlight or moisture. On the other hand, durable materials will not degenerate quickly with these factors as metal, plastics, and steel.

Enduring characteristics of metal, steel, and plastic

Generally, people select a durable material for most types of applications. Sometimes, a more enduring one is necessary to ensure the structure’s longevity. However, a less durable material may be acceptable if it is less expensive or easier to work with.

More things play a role in the durability of the material. These include its type, manufacturing process, environment, and intended use.

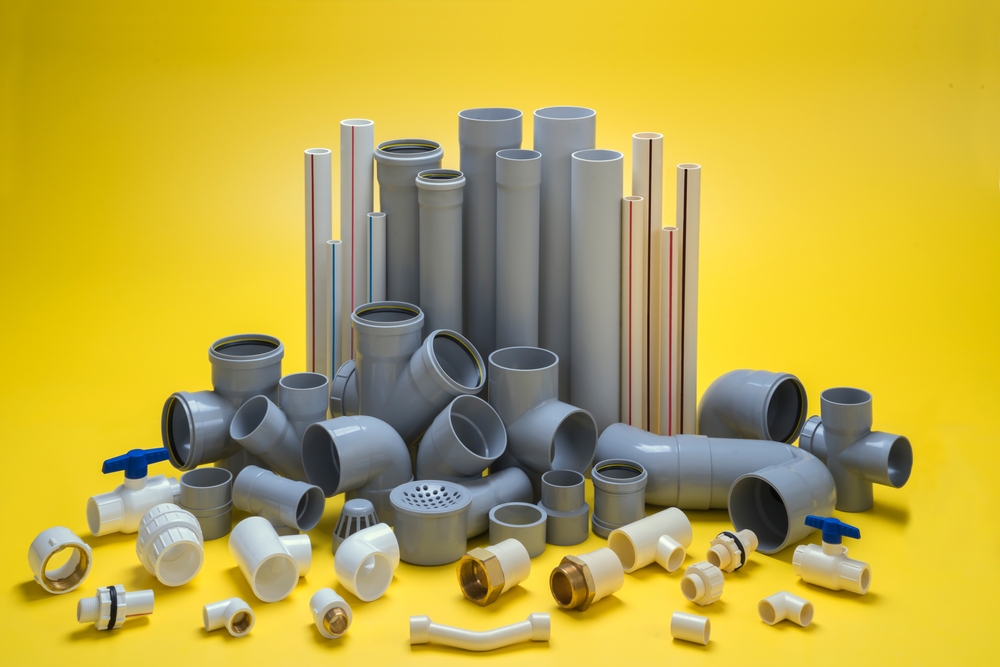

Plastics are durable materials that can be molded into various shapes and sizes. They resist most chemicals and are not easily damaged by physical forces. The advantages of plastic over other construction materials are its low cost, lightweight, and flexibility. It is also unsusceptible to rot, insects, and water.

However, plastics’ durability is not as strong as metal and steel. These are sensitive to UV damage and can become brittle over time.

Metals are generally very durable. They are insusceptible to wear and tear, fading, chipping, and corrosion. Some metals, such as aluminum, also have toughness against fire.

Metal has a better resistance against different damaging agents than plastic. Plus, it is a good heat and electricity conductor. However, metal is more expensive than plastic and can be challenging for most builders. Compared to steel, metal is heavier and less corrosion-resistant.

Steel is one of the most heavy-duty materials for being an alloy of iron and carbon. The properties of both elements make it not warp, weak in bearing load, split, etc.

One disadvantage of steel is it is more susceptible to corrosion if it’s constantly exposed to moisture and other elements. Some treatments are applied to make these more durable. It becomes stainless steel with the addition of chromium and nickel or galvanized steel when coated with zinc.

Overall, each material has its own unique set of benefits and drawbacks. When deciding which material to use for a particular application, it is crucial to consider the specific needs of the project and the factors that deter its durability.